SOLVAir® for Energy from Waste industries

Wekaya (Sharjah, UAE) - Medical and Hazardous Waste Management

SOLVAir® solutions helps Sharjah plant, Wekaya, meet UAE air emissions standards.

Case Study: MVA Weisweiler, a German Waste-to-Energy plant, switches to SOLVAir®

MVA Weisweiler, a German Waste-to-Energy plant, switches to SOLVAir®

Sludge incineration for european wastewater treatment

SOLVAir® removes SO2 from sludge incineration without heavy cost.

TRM, waste-to-energy plant in Italy

Getting rid of all acid gases in municipal waste incineration.

I.V.O.O., Energy from waste plant in Belgium

Treating NOx, SOx and HCl in waste management made easy thanks to SOLVAir®.

Syctom Waste to Energy plant in France

Mitigate HCl, SOx and HF to meet new regulations in the center of Paris.

ZAK Energie GmbH - Facility in Kempten, Germany

Meeting stringent new NOX Emission Limits with a tail-end Selective Catalytic Reduction (SCR)

Horgen, waste-to-energy plant in Switzerland

Reach the lowest possible emissions rate while allowing high energy recovery.

Waste Incineration plant in Canada

Reducing ash volumes while getting rid of HCl using less sorbent.

A2A AMBIENTE: A Waste-to-Energy plant in Italy

Mitigate SOx, HCl and NOx emissions while producing more energy.

ARA PUSTERIA /ARA PUSTERTAL sludge waste to energy plant in Italy

Remove high rates of SOx with small available space for flue gas treatment

SOLVAir® for Energy Production factory

Coal Fired Power Plant for Steam Production in Chile

Achieving lower Operating Expenditure (OPEX) for their sulfur dioxide (SO2) abatement.

Chilean Coal Fired Power Plant

Reducing SO2 emissions from a coal fired power plant while reducing logistics costs.

Coal Fired Power Plant in Chile

SOLVAir® solutions mitigates hydrated lime consumption and compliance with emissions regulations.

Solvay soda ash plant in Spain

Desulfurizing and dedusting exhaust from coal-fired steam boilers.

American Coal power plant

SO2 mitigation for a coal power plant close to an urban area.

Biomass steam boiler in Wismar, Germany

Reducing HCl and SO2 emissions with less logistic costs

SOLVAir® for Industrial plants

Glass Company in Chile

Respecting the required SO2 emission limits while recycling residues as raw material.

Cement Plant in Midwest USA

Maintaining compliance using existing DSI system switching to SOLVAir® Trona S200

Cement manufacturing plant in the USA

Granting a cement plant fuel flexibility and regulatory compliance.

Salonit, cement manufacturing in Slovenia

Facilitating the treatment of SO2 emissions in cement manufacturing.

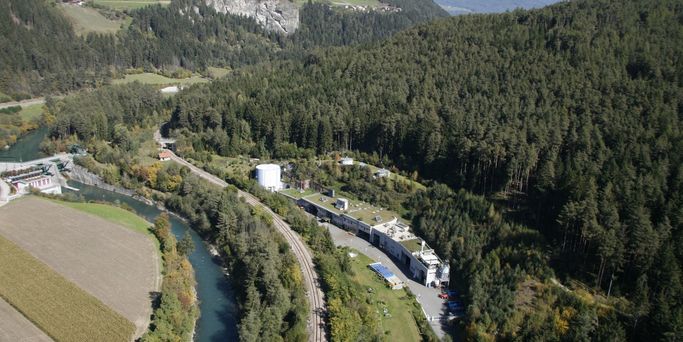

Voestalpine, sintering plant in Austria

Active plan of a sintering plant leader to clean his acides smokes.

Cement plant in the USA

Sorbent used for the flue gas treatment reduced by 25-30%

Solutions delivers cost-effective acid gas reduction treatment for smelter facility

Flue gas treatment alternatives are put to the test

SOLVAir® for Marine Industry

La Méridionale, a shipping company in France

Removing SOx and particle emissions from Piana