Capacity expansions in France and Italy meet the rising demand for SOLVAir® and enhance the use of circular raw material across Solvay's facilities in Dombasle and Rosignano.

Solvay has announced capacity expansions at its Resolest®* and Solval® units, specifically designed for recycling residues from the flue gas cleaning process using the market-leading SOLVAir® solution. The rising demand for this advanced technology stems from the enforcement of stringent environmental standards governing emissions across various industries. By the end of 2025, Resolest® is poised to undergo a significant 60% surge in recycling capacity. Likewise, commencing January 2024, Solval® is set to witness a substantial 30% increase in its capacity.

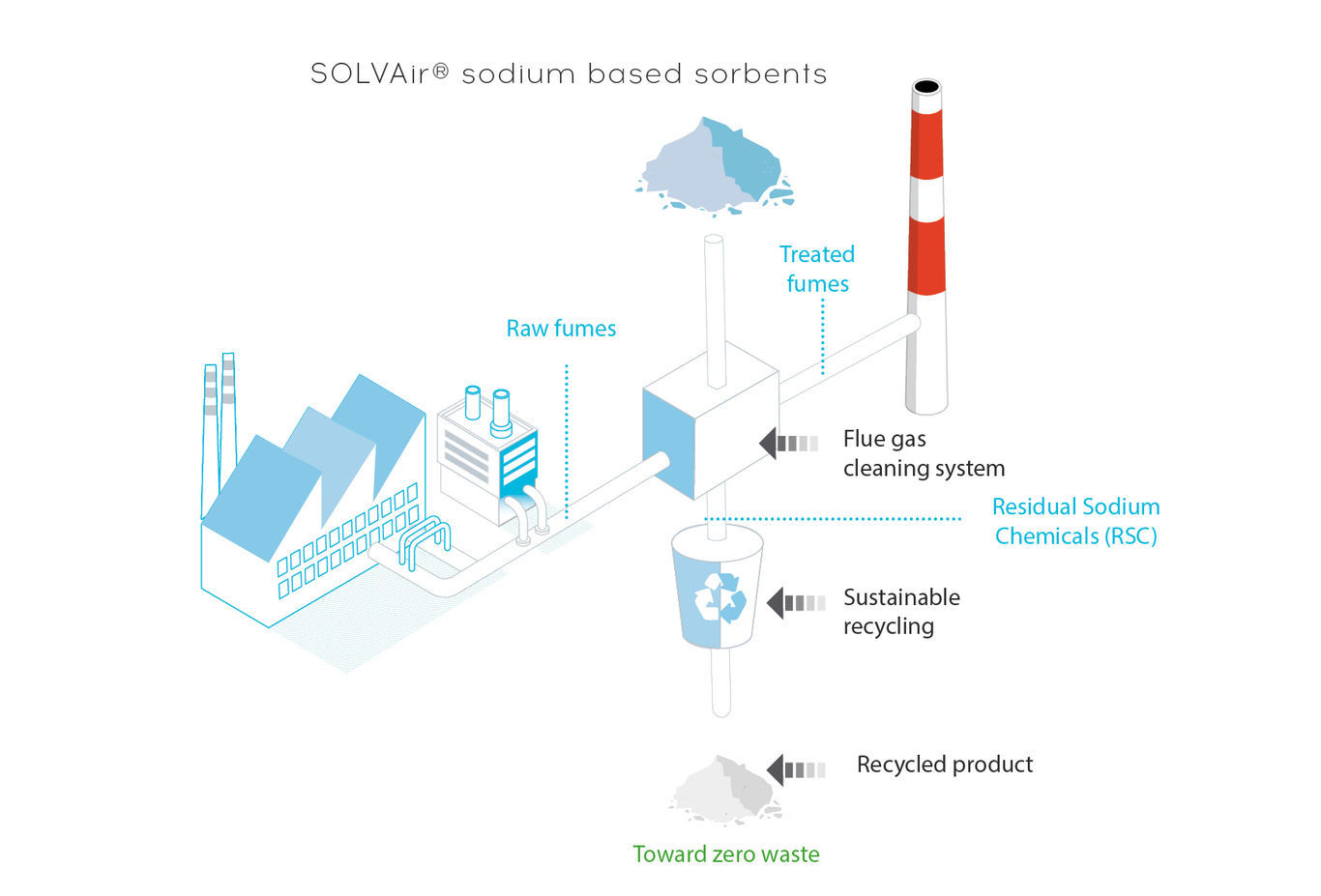

For decades, Solvay has been dedicated to establishing a circular economy for the residues generated from flue gas cleaning through SOLVAir® technology. More than 80% of SOLVAir® residue can be recycled into purified brine, serving as a circular raw material in soda ash manufacturing at Solvay's facilities in Dombasle, France, and Rosignano, Italy. This innovative process empowers both plants to reduce natural brine consumption, actively contributing to resource conservation.

"At Solvay, we're committed to providing sustainable solutions that address humanity’s essential needs. The high demand for our SOLVAir® breakthrough technology highlights its unique role in purifying air and preserving natural resources," said Philippe Kehren, Solvay CEO. "We're excited about contributing to the transformation and sustainability of various industries, fostering responsible business growth at Solvay. This aligns seamlessly with our dedication to a circular economy, supporting initiatives such as the European Green Deal and showcasing our unwavering commitment to sustainability."

SOLVAir® patented sodium-based solutions enable various industries such as waste-to-energy facilities, power plants, cement production, glass manufacturing and maritime vessels, to efficiently eliminate over 99% of pollutants. This ensures adherence to the strictest air emission regulations in place. In 2016, SOLVAir® was recognized as an environmentally-friendly solution by the Solar Impulse Foundation’s World Alliance.

* a joint-venture between Solvay and Sarp Industries