Efficient SOx cleaning for the carbon-based Industry

High tech materials

Carbon-based products such as graphite, cokes, carbon black, carbon fibers and carbon black are high-tech materials used in a wide range of applications, from electrodes to automotive parts, nuclear power plant components, and for environmental protection.

Pure carbon without impurities

These materials are produced by heating up raw materials containing carbon such as coal, coke, tars and heavy oil fractions, without the presence of oxygen to avoid combustion.

This process enables the elimination of all volatile impurities, resulting in a pure carbon product that can have various characteristics.

Acid gas generation

The flue gases generated by this process need to be treated by oxidation (thermal, catalytic or both) to avoid releasing harmful substances like carbon monoxide (CO), hydrogen sulfide (H2S) and VOC into the atmosphere.

The result of the oxidation process produces acid gases such as HCl, CO2, NOx and large amounts of SOx that have to be mitigated. The installation of a filtration device is also generally required to protect the equipment.

Carbon industry concerned by multiple legislations

In the EU legislation, various different BREF documents concern these products. Coke production falls under Iron & Steel, Graphite and carbon fiber in Nonferrous metals and Carbon Black in Large Volume Inorganic Chemicals.

What SOLVAir® can do for Coke, Graphite, Carbon fiber and Carbon black production?

Providing mitigation and protection

SOLVAir® solution consists in the injection of sodium bicarbonate as a dry sorbent for flue gas cleaning. It is the safest and most cost effective way to mitigate SOx emissions and protect the sensitive parts of the production plant.

The classic solution consists in injecting SOLVAir® sorbent into the flue gases before a bag filter, which efficiently mitigates SO2 and SO3. In the case of Carbon Black production, a second filter is often necessary.

Key benefits for carbon industry customers

Dry sorbent injection is a low capital cost option that efficiently meets treatment needs. Because of this, the SOLVAir® process is the best performing solution on the market, especially to mitigate SOx.

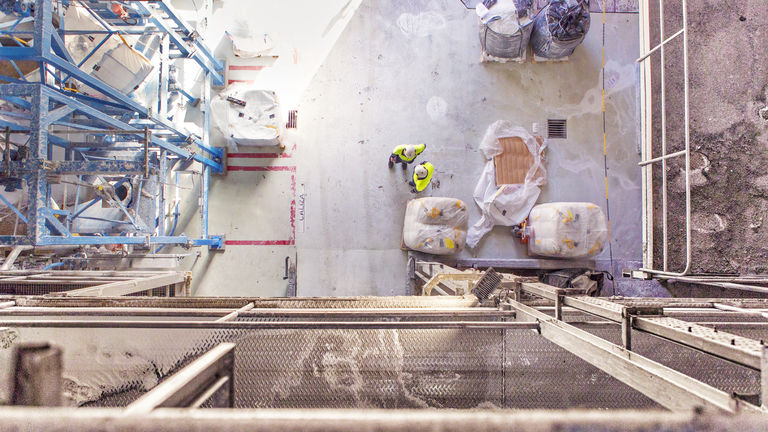

Quick installation of SOLVAir® Solution

Furthermore, the flue gas treatment equipment can be installed quickly, whether for trials or for permanent installation.

Case Studies

Read our case studies to get some data!

Contact

A question? Contact our team!