I.V.O.O. Key figures

19 years of collaboration, using SOLVAir® SB 0/3 (pre-milled bicarbonate based product) since 2014

67,000 tons of waste/year incinerated (target 2023)

Over 8,500 hours of operation/year

30,000 MWh of electricity and 20,000 MWh of heat produced per year

Pollutants to mitigate: HCl, SO2, NOx,

Facility located in Belgium

I.V.O.O.’s needs: cost efficiency and adaptability

A 19-year collaboration with Solvay

The Intermunicipality for waste management for Oostende and its surroundings on the Belgian seaside, has been producing energy from waste (EfW) since the 1980s. The company has been working with SOLVAir® for the past 19 years and its needs evolved during this time.

Complying with regulations on HCl, SO2 and NOx while reducing costs

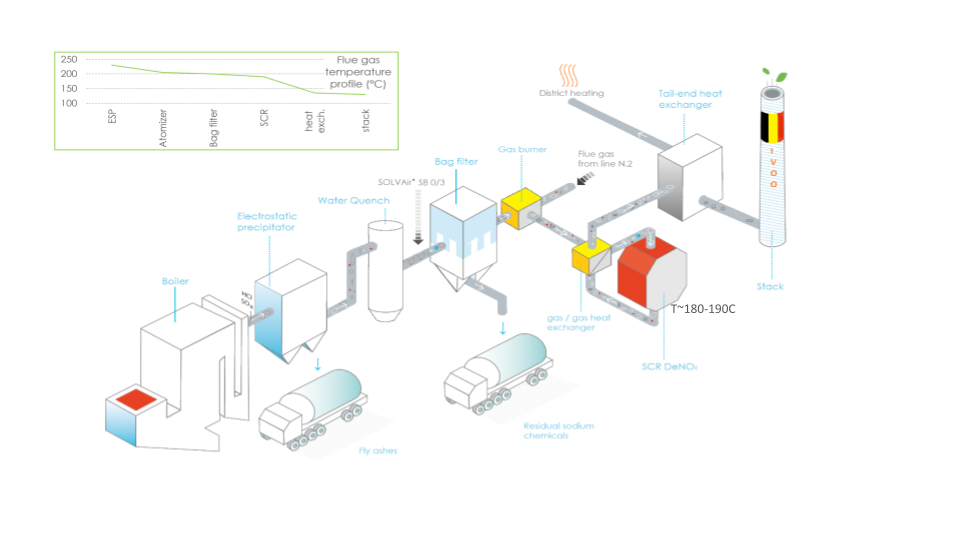

Over the course of all that time, the facility has had to comply with increasingly stringent regulations concerning its emissions, particularly sulfur dioxide (SO2), nitrogen oxides (NOx) and hydrogen chloride (HCl), while at the same time the waste was getting more and more polluted (HCl peaks in particular needed to be better controlled). On top of that, there was a need to reduce the total cost of ownership of flue gas treatment, combined with a will to increase the plant’s energy efficiency.

Variable waste input in a touristic area

A couple of additional issues specific to the its environment include a highly variable waste input, both in terms of quantity and quality, due to the touristic nature of the Belgian riviera, coupled with very low NOx emissions limits enforced by the Flanders region, and the relatively modest size of the facility (around 67,000 tons of waste incinerated and 30,000 MWh of electricity produced per year), making it all the more tricky to maintain the profitability of its EfW activity in the long term.

What SOLVAir® provides to I.V.O.O

Low investment and maintenance, high SOx mitigation

The first advantage of this solution was the absence of heavy investments needed to install and operate the SOLVAir® flue gas treatment system, which treats increasingly acid gases in compliance with current and future emissions limits. Moreover, contrary to a wet scrubber or a lime spray-drier and thanks to its simple and robust operation, the solution doesn’t use water. It therefore cannot produce any wastewater, which facilitates maintenance and operation, significantly reducing costs in the process. What’s more, it provides superior SOx mitigation performances without causing any energy losses due to flue gas treatment operations.

Innovation and experience for a tailor-made solution

SOLVAir® provided all the necessary technical assistance, thanks to our long-standing experience and our network of experts to optimize the installation. As an example, in 2014, in agreement with I.V.O.O., SOLVAir® decided to switch to a “ready-to-use” sorbent for the plant’s flue gas treatment. Given the requirements in terms of emissions limitations and energy output maximization, this was the way to go.

Benefits for I.V.O.O.

Flexibility and simplicity for operational excellence

With the installation of our solution, the Oostende EfW plant was able to maximize the flexibility of its flue gas treatment and enjoy the best possible operational experience.

Reminder (or look at the context !) : We are in a touristic area and waste is variable.

Improved cost and energy efficiency

Thanks to its low temperature NOx mitigation process in front of the SCR at 180-190°C, the flue gases doesn’t need to be reheated to get rid of the nitrogen oxides. SOLVAir® has successfully improved the plant’s energy efficiency and reduced its operating costs.

Green energy for local heating

Finally, the heat from the flue gases was more efficiently put to good use by being injected into the local heating network used by neighboring industrial facilities.

“By making the right investments, among which the installation of SOLVAir® S300 since 2004 and upgrade to SOLVAir® SB0/3 since 2014, I.V.O.O managed to keep its installation up-to-date, compliant to all regulations, and still profitable.”

“Over the last decade, SOLVAY has been building a robust technical partnership with I.V.O.O. SOLVAir®’s technical experts and commercial teams have been attentive to the customer’s requests and provided the appropriate tailor-made solutions to ensure its sustainable operation in the long term.”

Requirement of the legislation in the Flanders region, Belgium

- BAT (Best available techniques)

- AEL (Associated emission limits) according to European BREF

SOLVAir® solutions DSI results in I.V.O.O's plant

Species concentrations | Raw gas before cleaning | Daily average | Legislation (24 average) |

| Dust | < 1 | 10 | |

| HCl | 1400 / 5000 | 6 | 10 |

| SO2 | 300 / 400 | 7 | 50 |

| NOx | 200 / 400 | 90 | 100 |

| HG2 | 0.006 | 0.05 | |

| PCDD/F3 | < 0.003 | 0.1 |